COREu innovations for CO₂ transport and storage hubs

Introduction

Carbon Capture and Storage (CCS) is a critical building block for industrial decarbonisation in Europe. One of the key challenges in scaling CCS is the development of flexible, reliable and cost-efficient transport solutions that can connect diverse emitters to geological storage sites. Within the COREu project, two major technological innovations are being demonstrated that directly address this challenge:

GasVessel Production (GVP) carbon fibre cylinders

Technical Concept

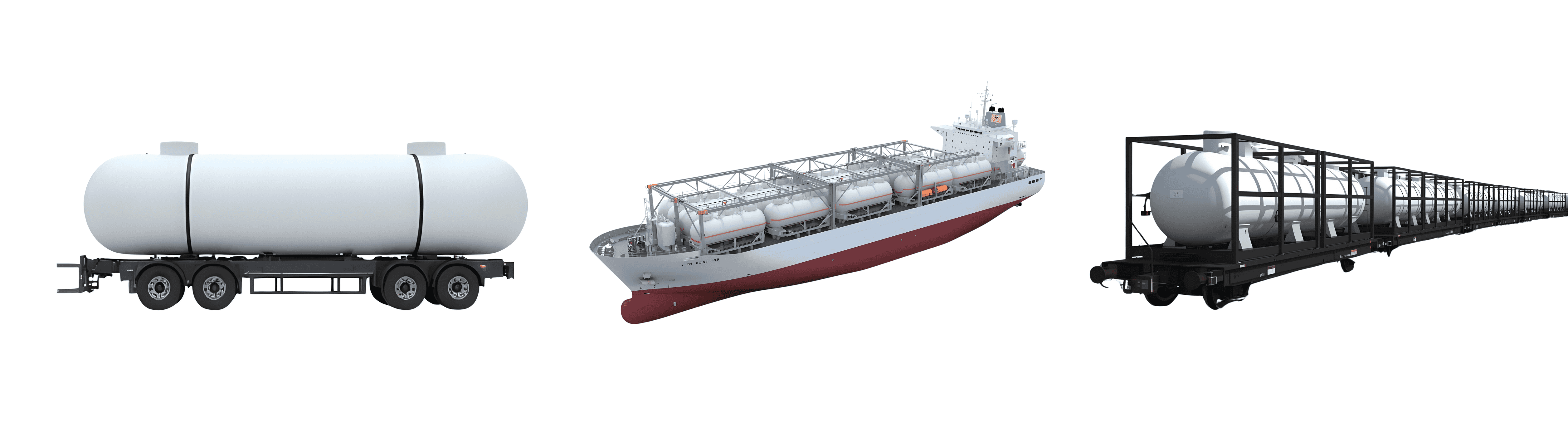

The GVP solution introduces high-pressure carbon fibre cylinders with stainless-steel liners for transporting captured and compressed CO₂. Unlike traditional liquefaction-based approaches, this system allows CO₂ to be loaded, stored and transported at ambient temperature. The cylinders are mounted in modular racks that can be deployed across trucks, rail wagons, and ships.

Advantages and Differentiators

- No liquefaction required: Avoids the energy-intensive process of cooling CO₂ to cryogenic temperatures (~−50 °C)

- Unlimited storage time: Cylinders safely hold CO₂ without boil-off losses

- Impurity tolerance: Stainless-steel liners prevent corrosion from trace gases such as SO₂ or NOₓ, common in captured CO₂ streams.

- Modular deployment: Cylinders can be scaled from pilot projects to full commercial hubs, bridging the gap until pipeline infrastructure becomes available.

- Multi-modal logistics: Compatible with trucks, rail, and short-sea shipping, providing maximum flexibility for regional clusters.

Relevance for CCS Hubs

This solution is particularly important for small and medium-sized emitters, which are often excluded from CCS networks due to high entry costs. GVP cylinders enable them to feed into regional collection hubs without major infrastructure investments, ensuring inclusivity and accelerating hub formation.

MacGregor direct offshore transfer for CO₂ injection

Technical Concept

For offshore storage, the current industry standard involves intermediate onshore facilities for temporary storage and conditioning before CO₂ is transported offshore and injected. MacGregor’s innovation demonstrates four different system architectures for direct transfer of CO₂ from ship to wellhead, eliminating or minimising the need for intermediate infrastructure.

The concept covers loading systems, transfer lines, and offshore injection units capable of operating in harsh maritime environments.

Advantages and Differentiators

- Direct ship-to-well injection: Reduces the need for costly onshore buffer terminals.

- Operational flexibility: Multiple system architectures are being tested to adapt to different offshore layouts and storage site conditions.

- Harsh-environment capability: Designs consider rough sea states, dynamic positioning, and flow assurance for stable CO₂ injection.

- Scalable solution: Direct offshore injection supports large volumes of CO₂ from regional hubs and integrates smoothly into cross-border maritime logistics.

Relevance for CCS Hubs

Direct ship-to-well transfer enables cross-border, large-scale maritime CO₂ transport. This is essential for connecting industrial clusters in Europe to offshore storage formations in the North Sea and beyond. By reducing infrastructure complexity, the innovation lowers investment risks and accelerates the operational rollout of CCS hubs.

Impact on CCS hubs and cross-border infrastructure

Both innovations support COREu’s mission to demonstrate flexible CO₂ transport solutions that underpin regional hubs and shared infrastructure in Europe. Together they:

- Connect emitters without direct access to pipelines

- Enable modular scaling of transport capacity

- Reduce costs and risks across the CCS value chain

- Strengthen cross-border connectivity for CO₂ storage

These developments contribute to Europe’s goal of establishing open-access CCS networks that allow industries of all sizes to decarbonise. They also provide real-world insights into regulatory, financial, and operational challenges, supporting COREu’s policy analysis and recommendations for a well-functioning European CO₂ market.